Warehouse Management System Overview

A Warehouse Management System (WMS) is a software application designed to support and optimize warehouse functionality and distribution center management. It facilitates the management of warehouse operations from the moment goods or materials enter a warehouse until they move out.

They can be standalone solutions or integrated with broader Enterprise Resource Planning (ERP) systems. At its core, a WMS provides tools for tracking inventory, managing workflows, and ensuring that goods move smoothly through the warehouse.

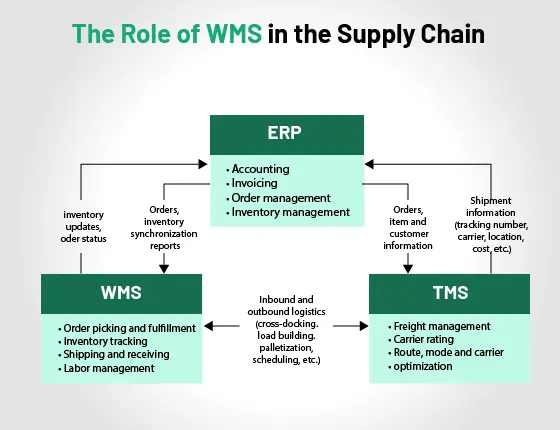

The Role of WMS in the Supply Chain

A WMS is a critical component of the supply chain, sitting at the center of inbound logistics (receiving goods), internal logistics (inventory management and order fulfillment), and outbound logistics (shipping goods). By optimizing these processes, a WMS ensures that goods are delivered to customers accurately and on time.

Who Uses Warehouse Management System Technology?

• Retailers: To manage stock levels and fulfill online and in-store orders efficiently.

• Manufacturers: To streamline the storage and retrieval of raw materials and finished products.

• Third-Party Logistics (3PL) Providers: To handle the warehousing needs of multiple clients.

• E-commerce Companies: To meet the fast-paced demands of online shopping.

• Healthcare Providers: To ensure the accurate and timely delivery of medical supplies.

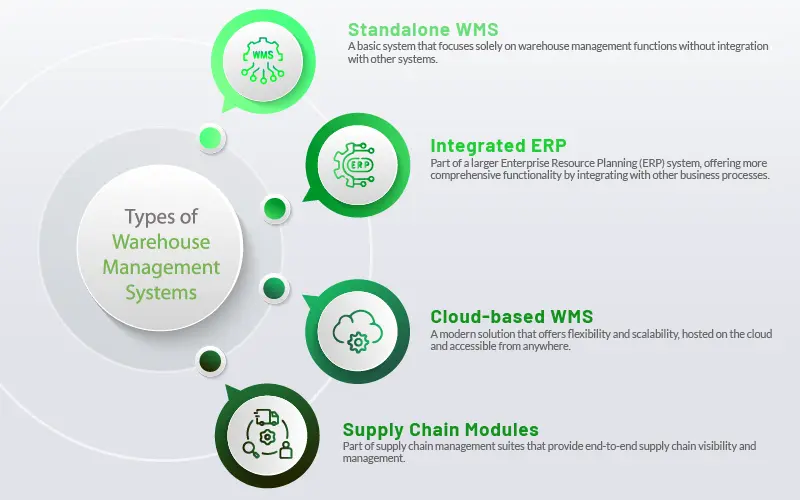

Types of Warehouse Management Systems

There are several types of WMS solutions:

- Standalone WMS: A basic system that focuses solely on warehouse management functions without integration with other systems.

- Integrated ERP: Part of a larger Enterprise Resource Planning (ERP) system, offering more comprehensive functionality by integrating with other business processes.

- Cloud-based WMS: A modern solution that offers flexibility and scalability, hosted on the cloud and accessible from anywhere.

- Supply Chain Modules: Part of supply chain management suites that provide end-to-end supply chain visibility and management.

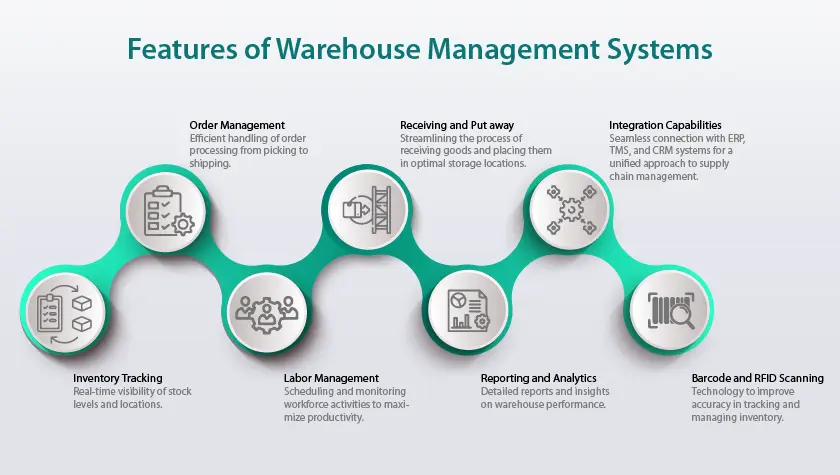

Features of warehouse management systems

A robust Warehouse Management System includes a variety of features designed to optimize warehouse operations:

• Inventory Tracking: Real-time visibility of stock levels and locations.

• Order Management: Efficient handling of order processing from picking to shipping.

• Labor Management: Scheduling and monitoring workforce activities to maximize productivity.

• Receiving and Putaway: Streamlining the process of receiving goods and placing them in optimal storage locations.

• Reporting and Analytics: Detailed reports and insights on warehouse performance.

• Integration Capabilities: Seamless connection with ERP, TMS, and CRM systems for a unified approach to supply chain management.

• Barcode and RFID Scanning: Technology to improve accuracy in tracking and managing inventory.

Benefits of a Warehouse Management System

1. Improved Inventory Accuracy: Real-time tracking reduces errors and discrepancies.

2. Enhanced Productivity: Automating tasks such as picking and packing increases efficiency.

3. Better Space Utilization: Optimized storage solutions maximize warehouse capacity.

4. Reduced Operational Costs: Efficient processes lead to lower labor and storage costs.

5. Higher Customer Satisfaction: Faster, more accurate order fulfillment improves the customer experience.

Modern, Cloud-Based Warehouse Management Systems

Benefits of Cloud-Based WMS

Modern WMS systems, especially those based in the cloud, offer numerous advantages:

- Scalability: Easily adjust to the changing needs of your business without significant investments in infrastructure.

- Accessibility: Access your WMS from anywhere with an internet connection, facilitating remote management and oversight.

- Cost-Efficiency: Reduce the need for physical servers and IT maintenance.

- Automatic Updates: Stay current with the latest features and security improvements without manual intervention.

- Integration Capabilities: Seamlessly connect with other systems like ERP, TMS (Transportation Management System), and CRM (Customer Relationship Management).

Cons of Cloud-Based WMS

While cloud-based WMS offers many benefits, there are some potential drawbacks:

- Dependence on the Internet: Any disruption in internet service can halt operations.

- Vendor Reliability: Dependence on the service provider for uptime and support.

The Integration of WMS and IoT

The integration of the Internet of Things (IoT) with WMS systems is revolutionizing warehouse management. IoT devices, such as sensors and RFID tags, provide real-time data on inventory levels, equipment status, and environmental conditions. This data helps in predictive maintenance, optimizing warehouse layout, and enhancing overall efficiency.

Smart Warehousing Technology

Smart warehousing leverages technologies like IoT, AI, and robotics to create highly automated and efficient operations. Smart warehouses can dynamically adapt to changes in inventory, demand, and other factors, leading to significant improvements in performance and cost savings.

Top Warehouse Management System Vendors

Some of the leading WMS vendors include:

• SAP Extended Warehouse Management (EWM): Known for its comprehensive features and integration capabilities.

• Oracle Warehouse Management Cloud: Offers robust cloud-based solutions for businesses of all sizes.

• Manhattan Associates: Provides advanced WMS with extensive analytics and optimization tools.

• Blue Yonder (formerly JDA): Known for its end-to-end supply chain solutions.

• Infor WMS: Offers scalable and flexible warehouse management solutions.

Implementation Strategies for WMS

1. Needs Assessment: Evaluate the specific needs of the warehouse to choose the right WMS solution.

2. Vendor Selection: Select a reputable vendor with experience in implementing WMS solutions in similar industries.

3. Customization and Integration: Customize the WMS to meet unique warehouse requirements and integrate with existing systems.

4. Training and Support: Provide adequate training to staff and ensure ongoing support for smooth operation.

5. Phased Implementation: Implement the WMS in phases to minimize disruptions and allow for gradual adaptation.

Future of Warehouse Management

The future of warehouse management lies in automation, AI, and robotics. Autonomous mobile robots (AMRs) and drones are expected to take on more roles in picking, inventory management, and even delivery. AI-driven analytics will provide deeper insights, enabling proactive decision-making and further optimization of warehouse operations.

Key Trends

- Artificial Intelligence and Machine Learning: Enhanced predictive analytics and automation.

- Internet of Things (IoT): Improved real-time tracking and monitoring of inventory and assets.

- Robotics and Automation: Increased use of robots for picking, packing, and transportation within warehouses.

- Blockchain Technology: Enhanced transparency and security in supply chain transactions.

- Augmented Reality (AR): Improved efficiency in picking and inventory management through AR-assisted tools.

WMS Plus - Warehouse Management System by FINAP

Why choose WMS Plus?

- End-to-End Transparency: Gain real-time visibility into your entire supply chain.

- Efficiency: Optimize warehouse processes for increased efficiency.

- Accuracy: Minimize errors in receiving, picking, and shipping.

- SAP Integration: Integrate with SAP or any other ERP system.

- Scalability: Grow your business with a scalable WMS solution.

System Modules

- User Management Module

- Barcode Printing Module

- Dispatching Module

- Goods Receipts Module

- Palletization Module

- Reporting Module